(Photo Credit: Katherine Lin/UC Davis College of Engineering)

Originally published in the San Francisco Chronicle, republished with author's permission

Is it true? That we don’t make anything in the U.S. anymore? That all our production has moved to China? That manufacturing has left California and isn’t coming back? That it’s too expensive to manufacture in the Bay Area? While many people think this — and there are reasons why they do — none of these statements holds today.

Manufacturing is in the early stages of a renaissance that will change our idea of what it means to manufacture. But we need to rebuild our pipeline of manufacturing industry workers and update those skill sets. Legislation before the Legislature now would strengthen programs at the state’s community colleges to train workers for these new jobs.

The governor is requesting $248 million in new funding for career technical education in his 2016-17 budget. A significant share of that funding would be distributed on a regional basis (not just to individual campuses) to ensure widespread collaboration with industry. Such an investment would help ensure manufacturing’s future in California’s economy.

Ask most people what they think of when they hear the word “manufacturing,” and they describe large factory floors with hundreds or thousands of relatively low-skilled assembly-line workers. While those places do exist, 21st century production is far different.

For example:

Complex products — from aircraft parts to, in the not-too-distant future, human organs — can now be produced from a growing array of materials with 3-D printing. This is enabling swift, customized production that serves local or specialized markets. With the growth of online commerce, consumers are increasingly demanding products (clothes or shoes custom-designed for a personal fit) that both meet their expectations and are immediately available.

Robotics and the Internet of Things — machines that are connected by sensors, and both generate and respond to big data — are enabling sophisticated processes that can produce high-volume goods with great precision.

Of course, Asian and other countries have access to these technologies, too. But labor rates in China are rising, and the cost savings relative to manufacturing in the United States — while still substantial — are shrinking. With labor becoming an ever smaller part of production costs, China’s advantage shrinks further. Add to that the desire of many U.S. manufacturers to shorten supply lines, better manage quality and retain the many benefits of U.S. research and development lost when production is off-shored, and we have a new competitive landscape.

Transformation is under way, and change is accelerating. What’s the takeaway for California and the Bay Area?

Don’t write off manufacturing. California is the largest manufacturing state in the nation. While overall employment has dropped, it has grown in key sectors, including medical devices, beverages (beer and wine) and biopharmaceuticals. The growth we’ve seen is built on our competitive strengths of technological innovation, established R&D efforts and a focus on high-value lifestyle products. This is particularly true for the Bay Area. Tesla Motors, for example, has spawned a regional network of automotive suppliers decoupled from Detroit.

Do what we can to keep down costs for business. For example, we could reform the California Environmental Quality Act, which was designed to protect the environment but is increasingly used by opponents to kill or delay construction of new manufacturing plants, often for non-environmental reasons.

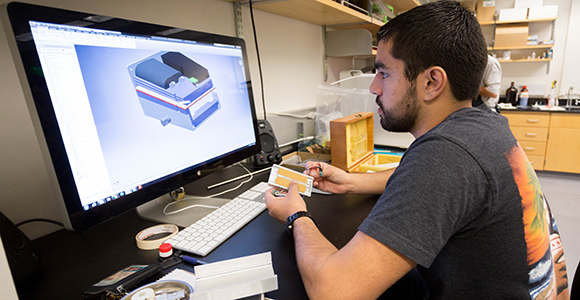

Encourage public and private “maker” spaces. These are places where entrepreneurs can build prototypes and try out their ideas using shared equipment that would be otherwise beyond their reach. Tech Shop, a maker space that started in the Bay Area, is a good example. SFMade, which provides space to help small manufacturers in San Francisco get going, is another.

Invest in our manufacturing workforce. More than half of production workers are older than 45, with a growing number nearing retirement. That’s why funding for training requested in the governor’s budget is vital. Schools already have created the Bay Area Community College Consortium to align educational priorities and industry needs so business gets the workers it needs and graduates find work for which they trained. In the future, community colleges want to develop a $10 million, 10-campus network of maker spaces to open across the state by December 2017. The $248 million for workforce training on the table now represents an important revitalization of career technical training, which the state has for too long neglected. The Legislature should approve the governor’s request.

Let’s be clear: Primarily because of automation, most of the manufacturing jobs that have gone away aren’t coming back. But for California, the new manufacturing world offers high-quality, high-skill jobs to those who acquire the technical skills. Manufacturing jobs bring solid — and, recently, rising — incomes. Manufacturing is important to a balanced economy — and something we all should care about.

Sean Randolph is senior director at the Bay Area Council Economic Institute (www.bayareacouncil.org). To read the institute’s report on “Reinventing Manufacturing,” go to http://bit.ly/1tmRNsZ.